Processing of Cocoa Beans

| There has been no change of processing of cacao beans from harvesting through drying. This is done in the producing countries. |

HarvestingOnce the flowers are pollinated the pods take 5-6 months to grow and mature to the yellowish red color of the ripened pod. The pods are harvested manually. Once harvested, they may keep for about a week before spoiling. After harvesting the pods are carefully cut open with machetes and the beans with the pulp are removed. These are then placed in large boxes, or just in heaps, covered with banana leaves and left to ferment. The fermentation process gives flavor to the beans and the pulp slowly liquefies and runs off as the temperature rises. This takes up to a week. The beans start to germinate in the first couple of days of fermentation, soon to be killed by the high heat produced by the fermentation. This stage is important since ungerminated beans lack flavor. The mass is turned from time to time so hot spots don't develop and the temperature is maintained at around 110F to 120F.The beans are then dried either on patios for a couple of weeks, or in an oven with continuous turning in order to reduce the moisture content to about 7%. Then the beans are packed to be sent to chocolate factories, mostly overseas. |

Roasting

Next, the roasted beans are broken down and the thin shell (chaff) is removed in the process called winnowing. The remaining pieces of kernel are called cacao nibs, which have the final chocolate flavor as we know it. Nibs contain about 400 different chemicals responsible for the flavor of the final products. | ||||||

Grinding

| ||||||

Filtering the Butter

The high quality gourmet chocolates are made from cacao liquore. | ||||||

Making Hot Chocolate MixThe cacao cake is pulverized by grinding, then mixed with ground sugar and milk powder, artificial shortening agents and lecithin are added, to make it easily mixed in water to form the drink. This is the typical commercial hot chocolate mix.The high quality gourmet hot chocolate like ours is made by pulverizing the cake, adding some cacao butter and evaporated sugarcane juice and also bits of dark chocolate. There is no dairy product or other additives. The prepared drink can be made using milk, rice milk, soymilk or water and spicing if desired. |

Making ChocolateThe cacao cake is ground and mixed with a little cacao butter, shortening, lecithin, pulverized confectionery sugar, flavorings and milk powder (for milk chocolate). The resulting mass is then mixed and ready for refining.High quality gourmet chocolates are made from cacao liquor, which is not filtered to remove the cacao butter. To this pulverized confectionary sugar and vanilla or other natural flavors, milk powder for milk chocolates, and a little lecithin are added. |

RefiningThe above mixture is refined through a series of rollers to give the chocolate its consistency by reducing the particle size of the mixture so that they cannot be felt on the tongue. The size is generally reduced to 20 millionth of a meter, smaller than the distance between two sensory taste buds in the mouth. The process also creates its own heat, which develops the flavor of the chocolate. |

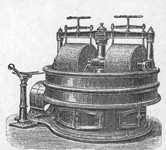

ConchingThe refined chocolate is further improved by grinding under rollers of machines called conch because the resemblance of its shape to a conch (shell). Here the refined chocolate is ground under granite rollers, which goes back and forth on a flat granite table with curved lips. When the rollers go back and forth on the lip, the mass splashes on to the roller towards the main body of the machine. This friction produces heat, develops the flavor and drives out volatile acids while masticating the material. The process takes 1 to 3 days.High quality gourmet chocolates are still manufactured using similarly designed equipment but the cheap commercial chocolate is produced on equipments using heat and paddles to stir the mass to remove the volatile acids and develop flavor. |

Tempering

Chocolate melts at about 98F, which is the body temperature, thus melting in the mouth. | ||||||